Munich, 10 July 2023 Our Ref.: SM 6775-01WO SOE/TWS Applicant: Symrise AG Serial Number: New Application Symrise AG Mühlenfeldstraße 1, 37603 Holzminden, Germany 3-Hydroxypropylesters as foam and viscosity modulating agents in surfactant containing formulations The present invention primarily relates to compounds of formula (I) as disclosed herein and their use for modifying the viscosity of a surfactant containing formulation and/or for modifying the foam quality of the same. It is one of a series of inventions related to 3- Hydroxypropylesters and structurally related compounds co-filed by the same applicant and on the same date as PCT patent applications, which are titled “3-Hydroxypropylesters as antioxidants and tocopherol boosters”, “3-Hydroxypropylesters as solubility enhancers for lipophilic ingredients”, “3-Hydroxypropylesters as foam and viscosity modulating agents in surfactant containing formulations”, “3-Hydroxypropylesters as emulsifying agents”, “3- Hydroxypropylesters as antimicrobial agents”, and “Antimicrobial synergies”, whose content is incorporated herein by way of reference. In shampoo products, viscosity is an important factor for it to be a functional product. Viscosity influences the cleansing efficiency, users’ perception, foaming properties, production filling, packaging, storage, and long-term stability. For instance, to meet customers’ expectations the liquid should be easily applicable to the skin while still adding a “rich” feeling. Liquids which are considered “rich” usually have a higher viscosity. Moreover, in order to improve the long-term stability during storage the viscosity of the liquid should be as high as possible, since the higher the viscosity is the lower the sedimentation of dispersed particles will be. Generally, water-soluble polymers such as polyquaternium 10 act as viscosity modifiers (i.e. thickening agent) to increase the viscosity. Sodium chloride can be used to thicken anionic surfactant-based formula. * *202230572533385*75338*

Surfactants form the core of all shampoo formulations, and contribute to a wide range of different benefits, including cleansing, foaming, rheology control, skin mildness and the deposition of benefit agents to the hair and scalp. Surfactants traditionally used in the cosmetic industry are sulfates such as sodium laureth sulfate, sodium lauryl sulfate and ammonium laureth sulfate. While being effective in terms of cleansing and rheology control, they are considered problematic for the protective lipid layer of the skin. As a consequence, sulfate-free products have been developed. A disadvantage of sulfate-free products is that their viscosity is more difficult to set as they cannot be thickened with sodium chloride, and that they tend to have poorer foaming properties. The viscosity can be increased by using more polymers in sulfate free formulations, however, this is on cost of the foaming properties. Surfactant based formulations not only form the core of shampoo products; also other personal care products, e.g., skin cleansing products, or household products, e.g., dish washing products or surface cleaners, are surfactant based. It was thus an object of the present invention to provide surfactant-based formulations whose viscosity can be easily set within the range desirably for personal care and household products. In particular, it was an object to provide personal care products or household products, in particular shampoos, that are capable of adding a rich feeling to a consumer’s skin, even when used in the form of a sulfate-free formulation. An additional, albeit optional, aim was that the surfactant-based formulations create a pleasant, in particular creamy, foam. The above objects are achieved by the various aspects of the present invention. A first aspect of the present invention pertains to the use of at least one of compounds of formula (I) for modifying the viscosity and/or for modifying the foam quality of a surfactant containing formulation. The compounds of formula (I) as described herein are defined as follows:

wherein R is selected from the group consisting of:

! n-nonyl,

! n-undecyl,

That is, the compounds encompassed by the above definition are 3- hydroxypropyldecanoate when R is n-nonyl and 3-hydroxypropyldodecanoate (when R is n-undecyl. 3-hydroxypropyldecanoate and 3-hydroxypropyldodecanoate have the structures of formula (1-a) and formula (1-b), respectively:

. In another aspect of the present invention, a method of modifying the viscosity and/or of modifying the foam quality of a surfactant containing formulation comprises or consists of the following steps: (a) providing at least one of compounds of formula (I) as defined herein (b) providing a surfactant containing base formulation, and (c) mixing the compound(s) of step (a) with the base formulation of step (b) in an amount sufficient to reach a predetermined viscosity and/or foam quality. The property of the herein described compounds of formula (I) characterized by the term “modifying the viscosity” can be determined by measuring the viscosity of a surfactant- based formulation containing at least one of the compounds of formula (I) as compared to a corresponding surfactant-based formulation lacking the at least one of the compounds of formula (I). The phrase “modifying the viscosity” is preferably an increase of the viscosity obtained by adding at least one of the compounds of formula (I) to a surfactant containing base formulation, i.e. a base formulation containing at least one surfactant, as compared

to the surfactant containing base formulation to which not the at least one of the compounds of formula (I) was added. The skilled person knows different methods for determining the viscosity, which are also applicable to determine a viscosity difference between a surfactant containing base formulation including at least one of the compounds of formula (I) and a surfactant containing base formulation lacking the at least one of the compounds of formula (I). In case different methods give different results, the viscosity is determined using a Thermo Scientific Haake RheoStress1 device with the following parameters Geometry: C60/1° Ti L; temperature 23°C; shear frequency 10 s

-1. The property characterized by the expression “modifying the foam quality” can be determined by measuring the foam quality of a surfactant-based formulation containing at least one of the compounds of formula (I) as compared to a corresponding surfactant based formulation lacking the at least one of the compounds of formula (I). The phrase “modifying the foam quality” is preferably one or more of a decrease of foam droplet size, thicker foam perception and creamier foam perception, obtained by adding at least one of the compounds of formula (I) to a surfactant containing base formulation as compared to the surfactant containing base formulation to which not the at least one of the compounds of formula (I) was added. The foam can be evaluated in accordance with the methods given in the example section. A surfactant-based formulation forms a further aspect of the present invention. The surfactant-based formulation comprises the following constituents: (i) at least one of compounds of formula (I) as defined herein, and (ii) at least one surfactant. A ”surfactant based formulation” is a formulation that contains a surfactant, i.e. at least one surfactant. Surfactants are an amphiphilic class of molecules, having both a hydrophilic and a hydrophobic part. The nature of the hydrophilic moiety is commonly used to classify surfactants in four basic categories: anionic, cationic, amphoteric and non-ionic. This class of chemicals has an ability to modify the properties of a surface and an interface. They can perform diverse functions including: cleaning, wetting, emulsification, solubilization, dispersion, foaming, penetration enhancement and antimicrobial activity. Due to this functional diversity, surfactants may be applied in production and processing of foods, agrochemicals, pharmaceuticals, personal care and laundry products, petroleum, mineral oils, lubricants, and paints. In cosmetic products surfactants may serve as detergents

(cleansing agents), emulsifiers, wetting or foaming agents, opacifiers, thickening agents, foam depressors, hair conditioners and antistatic agents. The phrase “base formulation” as used herein means an intermediate product that does not include all ingredients of the final formulation, and in particular does not include a compound of formula (I). The expression “an amount sufficient to reach a predetermined viscosity and/or foam quality” as used herein denotes an amount of the compound of formula (I) that provides a tangible modification of the viscosity and/or of the foam quality. In particular, the expression means that a tangible viscosity increase of the surfactant based formulation containing the compound of formula (I) can be observed as compared to a corresponding surfactant based formulation lacking the compound of formula (I). In the studies leading to the present invention as specified hereinafter, the inventors surprisingly found that the compounds encompassed by the above definition, i.e. 3- hydroxypropyldecanoate when R is n-nonyl and 3-hydroxypropyldodecanoate when R is n- undecyl, bring about a substantial viscosity increase when added to a surfactant containing formulation. Moreover, while not having completed all studies yet, the inventors suggest that not only the viscosity can be increased, but also a better, in particular creamier, foam can be achieved with the mentioned 3-hydroxypropoyl esters described herein. These observations can be usefully exploited within the context of personal care or household formulations. Altogether, the herein disclosed 3-hydroxypropoyl esters are capable of imparting a personal care or household formulation, in particular a shampoo or a hand dishwashing detergent formulation, with a desirable property profile including, but not limited to, a thicker and creamier appearance. Further aspects of the present invention will arise from the description below, in particular from the examples, as well as from the attached patent claims. According to a preferred embodiment of the present invention, the formulation is a personal care or a household formulation. Preferably, the formulation is selected from the group consisting of formulations of shampoos, conditioners, hair styling, intimate gels, concentrates, solid formulations, micellar waters, hand dishwashing detergents, auto dishwashing detergents, all purpose cleaners, floor cleaners, kitchen cleaners.

Preferred formulations include a surfactant system. A surfactant system refers to a combination of two or more different surfactants. The surfactant system preferably comprises: ! at least one anionic surfactant and/or at least one nonionic surfactant; and ! optionally, at least one surfactant selected from the group consisting of amphoteric, zwitterionic and cationic surfactants. In preferred embodiments, the surfactant system is free of sulfate containing surfactants. Yet more preferred are formulations being sulfate-free. Sulfates are a type of surfactant, which when combining with water, lather into a rich, foamy substance. Sulfates also help strip the hair of dirt and oil, but can also strip moisture from strands during the process. This can result in breakage, damage, split ends, and dry, frizz hair as well as dry, itchy scalp. These drawbacks can be avoided by using sulfate free surfactants. Moreover, the surfactant may be a biosurfactant, i.e. of microbial origin or prepared or derived from biobased starting materials comprising only non-fossil fuel-based carbon. Assessment of the biobased carbon in a material can be performed as further described below. Preferred surfactant(s) include the following: If an anionic surfactant (A) is present, it is preferably selected from the groups A-1 to A-5: (A-1) Acylamino acids (and their salts), such as ! acylglutamates, for example sodium acylglutamate, di-TEA- palmitoylaspartate and sodium caprylic / capric glutamate, ! acyl peptides, for example palmitoyl-hydrolyzed milk protein, sodium cocoyl- hydrolysed soy protein and sodium / potassium cocoyl-hydrolyzed collagen, ! sarcosinates, for example myristoyl sarcosine, TEA-lauroyl sarcosinate, sodium lauroyl sarcosinate and sodium cocoyl sarcosinate, ! taurates, for example sodium lauroyl taurate and sodium methyl cocoyl taurate, ! acyl lactylates, lauroyl lactylate, caproyl lactylate, ! alaninates;

(A-2) Carboxylic acids and derivatives, such as ! carboxylic acids, for example lauric acid, aluminum stearate, magnesium alkoxide and zinc undecylenate, ! ester carboxylic acids, for example calcium stearoyl lactylate, laureth-6-citrate and sodium PEG-4-lauramide carboxylate, ! Ether carboxylic acids, for example sodium laureth-13-carboxylate and sodium PEG-6-cocamide carboxylate; (A-3) Phosphoric acid esters and salts such as DEA-oleth-10-phosphate and dilaureth-4- phosphate; (A-4) Sulfonic acids and salts, such as ! acyl-isethionates, e.g. sodium / ammonium cocoylisethionate, ! alkylaryl sulphonates, ! alkyl sulfonates, for example sodium coconut monoglyceride sulfate, sodium CM-U olefin sulfonate, α-olefin sulfonate like C14-16 olefin sulfonate,e sodium lauryl sulfoacetate and magnesium PEG-3 cocamide sulfate,sulfosuccinates, for example dioctyl sodium sulfosuccinate, disodium laureth sulfosuccinate, Dinatrium laurylsulfosuccinat and disodium undecylenamido MEA sulfosuccinate; (A-5) Sulfuric acid esters, such as ! alkyl ether sulfate, for example sodium, ammonium, magnesium, MIPA, TIPA- laureth sulfate, sodium myreth sulfate and sodium C 12-13 -parethsulfate, ! alkyl sulfates, for example sodium, ammonium and TEA lauryl sulfate. If an amphoteric surfactant (B) is present, it is preferably selected from the groups B-1 to B-3: (B-1) Cocamidopropyl betaine, (B-2) Acyl / dialkylethylenediamine, for example sodium acylamphoacetate, disodium acyl amphodipropionate, dinatnumalkylamphodiacetat, sodium acylamphohydroxypropylsulphonate, disodium acylamphodiacetate and sodium acylamphopropionate,

(B-3) N-alkylamino acids, for example aminopropylalkylglutamide, alkylaminopropionic acid, sodium alkylimidodipropionate and lauroamphocarboxyglycinate. If a non-ionic surfactant (C) is present, it is preferably selected from the groups C-1 to C-9: (C-1) Alcohols, (C-2) alkanolamides, such as cocamide MEA / DEA / MIPA, (C-3) amine oxides, such as cocoamidopropylamine oxide, (C-4) esters formed by esterification of carboxylic acids with ethylene oxide, glycerol, sorbitan or other alcohols, (C-5) ethers, for example ethoxylated / propoxylated alcohols, ethoxylated / propoxylated esters, ethoxylated / propoxylated glycerol esters, ethoxylated / propoxylated cholesterols, ethoxylated / propoxylated triglyceride esters, ethoxylated propoxylated lanolin, ethoxylated / propoxylated polysiloxanes, propoxylated POE ethers and alkyl polyglycosides such as lauryl glucoside, decyl glycoside and cocoglycoside, (C-6) sucrose esters, sucrose ethers, (C-7) polyglycerol esters, diglycerol esters, monoglycerol esters, (C-8) methyl glucose esters, esters of hydroxy acids; and (C-9) glycolipids, rhamnolipid, sophorolipid. If a cationic surfactant (D) is present, it is preferably selected from the group consisting of benzyl dimethylstearyl ammonium chloride, cetrimonium chloride, trimethyl ammonium chloride or bromide, lauryl or cetyl pyridinium chloride, alkyl dimethyl amine oxides or alkyl aminoethyl dimethyl amine oxides, benzalkonium chloride, polyquaternium-6, polyquaternium-7, polyquaternium-10, polyquaternium-22, polyquaternium-37, cocamide MEA, guar hydroxypropyltrimonium chloride, If a sulfate-free surfactant system (E) is present, one, several or all surfactants in the sulfate-free surfactant system is/are preferably selected from the group consisting of

dimethyl lauramide/myristamide, cetyl betaine, lauramidopropyl betaine, cocamidopropyl betaine, coco-betaine, almondamidopropyl betaine, apricotamidopropyl betaine, avocadamidopropyl betaine, babassuamidopropyl betaine, behenamidopropyl betaine, behenyl betaine, capric/lauric/myristic/oleic amidopropyl betaine, capryl/capramidopropyl betaine, cocamidoethyl betaine, coco/sunfloweramidopropyl betaine, cupuassuamidopropyl betaine, hippophae rhamnoidesamidopropyl betaine, isostearamidopropyl betaine, lauryl betaine, macadamiamidopropyl betaine, meadowfoamamidopropyl betaine, myristyl betaine, oleamidopropyl betaine, oleyl betaine, palmamidopropyl betaine, palm kernelamidopropyl betaine, pineamidopropyl betaine, ricinoleamidopropyl betaine, shea butteramidopropyl betaine, soyamidopropyl betaine, undecyleneamidopropyl betaine, wheat germamidopropyl betaine, rhamnolipids, sophorolipids, glycolipids, sodium lauryl glucose carboxylate, sodium cocoamphoacetate, PEG-7 glyceryl cocoate, cocamide DEA, cocamide MEA, lauramide DEA, glycol distearate, lauryl glucoside, caprylyl/capryl glucoside, decyl glucoside, coco glucoside, glycereth-26 arachidyl glucoside, butyl glucoside, C9-11 alkyl glucoside, C20-22 alkyl glucoside, cetearyl glucoside, heptyl glucoside, hydroxystearyl glucoside, isostearyl glucoside, myristyl glucoside, sodium cocoyl glutamate, alkyl glutamates, disodium cocoyl glutamate, sodium lauroyl glutamate, ammonium cocoyl isethionate, sodium cocoyl isethionate, sodium lauroyl methyl isethionate, sodium lauroyl lactylate, cocamido MEA, PEG-55 propylene glycol oleate, PPG-5-ceteth-20, disodium cocoamphodipropionate, sodium lauroyl sarcosinate, ammonium cocoyl sarcosinate, sodium oleoyl sarcosinate, sodium cocoyl sarcosinate, sodium myristoyl sarcosinate, isopropyl lauroyl sarcosinate, MIPA- cocoyl sarcosinate, potassium lauroyl sarcosinate, sodium palmitoyl sarcosinate, TEA- cocoyl sarcosinate, TEA-lauroyl sarcosinate, TIPA-lauroyl sarcosinate, sodium lauryl sulfoacetate, sodium caprylyl sulfonate, sodium dodecylbenzene sulfonate, sodium xylene sulfonate, sodium C12-C14 olefin sulfonate, sodium dioctyl sulfosuccinate, diethylhexyl sodium sulfosuccinate, disodium laureth sulfosuccinate, sodium methyl cocoyl taurate, sodium taurine cocoyl methyltaurate, sodium methyltaurate isopalmitamide, sodium methyl stearoyl taurate, sodium methyl palmitoyl taurate, sodium methyl oleoyl taurate, sodium methyl myristoyl taurate, sodium methyl lauroyl taurate, sodium N-isostearoyl methyltaurate, sodium cocoyl taurate, and sodium caproyl methyltaurate. rapeseed sophorolipids, hydrolyzed palm sophorolipids, rhamnolipids, glycolipids. In a particular preferred embodiment, the surfactant system comprises one or more of sodium laureth sulfate, lauryl glycoside, cocoamidopropyl betaine and polyquaternium-10.

In preferred embodiments, the formulation comprises the at least one compound of formula (I) in an amount of 0.01 to 10 wt.-%, preferably 0.05 to 2.5 wt.-%, more preferably 0.1 to 1.0 wt.-%, based on the total weight of the formulation. In this range, a profound viscosity increase is observed. The viscosity increase, as compared to a corresponding formulation lacking the compound of formula (I), may be at least 50%, at least 100%, at least 150%, at least 200%, at least 250%, at least 300%, at least 350%, at least 400%, at least 450%, at least 500%, or even more than 500%. In a further preferred embodiment of the present invention, the formulation comprises 5 to 90 wt.-%, preferably 10 to 80 wt.-% of the at least one surfactant, based on the total weight of the formulation. Preferred formulations further comprise at least one linear alkanediol having a carbon chain of 5 to 12 carbon atoms. In a still preferred variant, the linear alkanediol is a 1,2-alkanediol, a 2,3-alkanediol, a 3,4-alkanediol, a 1,3-alkanediol, or a mixture thereof, more preferred a 2,3-alkanediol or a 1,3-alkanediol. Most preferred linear alkanediols are selected from the group of 1,2-pentanediol, 1,2-hexanediol, 1,2-heptanediol, 1,2-octanediol, 1,2-nonanediol, 1,2-decanediol, 1,2-undecanediol and 1,2-dodecanediol. While linear alkanediols are variously used in the art due to their advantageous property profile, they also tend to be disadvantageous because of their viscosity reducing effect. Initial observations of the inventors surprisingly indicated that the compounds of formula (I) are able to compensate, and even seem to override, the negative effect of alkanediols in surfactant based formulations. Yet preferred formulations comprise the at least one compound of formula (I) and the at least one surfactant in a weight ratio of 0.0005:1 to 2:1, preferably 0.001:1 to 1:1, more preferably 0.005:1 to 0.5:1, most preferably 0.01:1 to 0.1:1. Optional constituents of formulations as described herein include on or more of the following: abrasives, anti-acne agents, agents against ageing of the skin, anti-cellulitis agents, anti-dandruff agents, anti-inflammatory agents, anti-microbial agents, irritation- preventing agents, irritation-inhibiting agents, antioxidants, astringents, odor absorbers, perspiration-inhibiting agents, antiseptic agents, anti-statics, binders, buffers, carrier materials, chelating agents, cell stimulants, cleansing agents, depilatory agents, surface- active substances, deodorizing agents, antiperspirants, softeners, emulsifiers, enzymes, enzyme inhibitors, essential oils, fibers, film-forming agents, fixatives, foam-forming agents, foam stabilizers, substances for preventing foaming, foam boosters, gelling agents, gel-

forming agents, hair care agents, hair-setting agents, hair-straightening agents, moisture- donating agents, moisturizing substances, moisture-retaining substances, bleaching agents, strengthening agents, stain-removing agents, optically brightening agents, impregnating agents, dirt-repellent agents, dyes, friction-reducing agents, lubricants, moisturizing creams, ointments, opacifying agents, plasticizing agents, covering agents, polish, preservatives, gloss agents, green and synthetic polymers, powders, proteins, re- oiling agents, abrading agents, silicones, skin-soothing agents, skin-cleansing agents, skin care agents, skin-healing agents, , skin-protecting agents, skin-softening agents, hair promotion agents, cooling agents, skin-cooling agents, warming agents, skin-warming agents, stabilizers, , UV-absorbing agents, UV filters, primary sun protection factors, secondary sun protection factors, detergents, fabric conditioning agents, suspending agents, , actives modulating hair pigmentation, matrix-metalloproteinase inhibitors, skin moisturizing agents, glycosaminoglycan stimulators, TRPV1 antagonists, desquamating agents, anti-cellulite agents or fat enhancing agents, hair growth activators or inhibitors, thickeners, rheology additives, vitamins, oils, waxes, pearlizing waxes, fats, phospholipids, saturated fatty acids, mono- or polyunsaturated fatty acids, α-hydroxy acids, polyhydroxyfatty acids, liquefiers, dyestuffs, colour-protecting agents, pigments, anti- corrosives, fragrances or perfume oils, aromas, flavouring substances, odoriferous substances, polyols, electrolytes, organic solvents, and mixtures of two or more of the aforementioned substances. Preferred constituents of formulations as described herein include on or more of the following: agents against ageing of the skin, anti-microbial agents, antioxidants, chelating agents, emulsifiers, surfactants, preservatives, green and synthetic polymers, skin-cooling agents, rheology additives, oils, fragrances, perfume oils, and polyols. Particular preferred constituents include at least one preservatives (different from the compounds of formula (I) and the surfactants as described herein). Examples of the aforementioned optional and preferred constituents as well as further constituents that can be included in the preparations as described herein can be found in paragraphs [0284] to [0351] of WO2022/122935. Moreover, the compounds of formula (I) are to be understood as preferred compounds of the present disclosure only, and the aspects, embodiments, features and effects described in conjunction with the compounds of formula (I) are to be understood to be correspondingly applicable to the compounds of formula (II). This means, for instance, that the compounds of formula (II) can be used for the purposes, in the methods or in the preparations, as

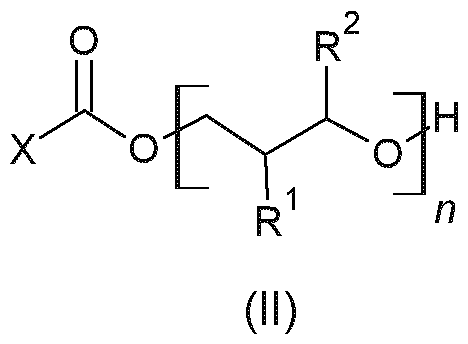

described herein in place of the compounds of formula (I). It likewise means, for example, that in preferred compounds of formula (II), X is as defined in formula (I), or that preferred preparations may comprise the compounds of formula (II) in the same amount as described for the compounds of formula (I). The compounds of formula (II) are defined as follows: with n = 1-10

wherein X is: ! straight-chain C5 - C14, preferably C6 - C14, more preferably C7 - C13, yet more preferably C

8 - C

12, most preferably C

9 - C

11, alkyl or alkenyl; or ! selected from the group consisting of:

with R

3 being -OCH3, -OCH2CH3, or -O(CH2)2CH3, wherein if n = 1: ! R

1 is selected from the group consisting of -H and -OH, and R

2 is selected from the group consisting of -H, -CH2(OH), -CH(OH)-CH2(OH), and -CH(OH)-CH(OH)- CH2(OH); or

! R

1 is -OH, and R

2 and the -OH group shown in formula (II) are joined together to form the following compound of formula (II-a):

! R

1 and R

2 are joined together to form the following compound of formula (II-b):

wherein if n = 2-10, R

1 is -OH, and R

2 = -H.

When X is , R

3 (as defined above) can be on any one of the free carbon atoms of the benzyl ring, i.e. X can be selected from the group consisting of:

. Structures of particular interest are:

Examples: In the following, the inventors’ research on the influence of the 3-hydroxyproylester of the present invention on the viscosity and foam properties of exemplary surfactant based formulations is shown. To this end, typical shampoo formulations were used as base formulations, and 3-hydroxyproylesters added thereto. It shall be emphasized that the observations made for these exemplary shampoo formulations are not confined to these specific shampoo formulations, but can be transferred to other formulations that include a surfactant, in particular those described herein. 1. Tested materials and formulations 1.1 Materials IUPAC Structure 3-Hydroxypropyldecanoate O O

OH 3- O Hydroxypropyldodecanoate O

OH The compounds of formula (I) can be obtained, for instance, by following the synthetic approaches described in Synthesis, 2003, (15), 2373-2377; Journal of the Korean Chemical Society, 2002, 46(5); and Tetrahedron Letters, 2015, 56(15), 1973-1975. 1.2 Formulations (amounts in wt.-percent) a) Sulfate-containing shampoo formulation (pH 5.8) w/w% Phase Material 01 02 03 04 05 A Sodium Laureth Sulfate, Lauryl Glycoside 17.0 17.0 17.0 17.0 17.0 Citric Acid 0.1 0.1 0.1 0.1 0.1 Caprylyl Glycol,1,2 Hexanediol 1.0 1.0 1.0 1.0 1.0 Sodium Gluconate 0.1 0.1 0.1 0.1 0.1 Sodium Chloride 0.4 0.4 0.4 0.4 0.4 B Water (Aqua) Ad 100 Polyquaternium-10 0.2 0.2 0.2 0.2 0.2

C Potassium Sorbate 0.15 0.15 0.15 0.15 0.15 D Cocoamidoproyl Betaine 5.0 5.0 5.0 5.0 5.0 Aqua (water), Citric acid 0.2 0.2 0.2 0.2 0.2 E 3-Hydroxypropyldecanoate - 0.5 1.0 - - 3-Hydroxypropyl dodecanoate - - 0.5 1.0 The sulfate-containing shampoo formulations were prepared as follows: Blend Phase A by gentle stirring slowly with a glass stirrer, stop the process when foaming starts. Swell Polyquaternium-10 in water by stirring and warming up to 50°C. Add Phases B, C and D to Phase A one after the other by stirring. Add the corresponding test materials (Phase E) by gentle stirring. b) Sulfate free shampoo formulation (pH 5.5) w/w% Phase Material 01 02 03 04 05 A Lauryl Glycoside 11.4 11.4 11.4 11.4 11.4 B Coco Glycoside 5.6 5.6 5.6 5.6 5.6 Water (Aqua) Ad 100 Sodium Cocoamphoacetate, 18.0 18.0 18.0 18.0 18.0 Glycerin, Lauryl Glycoside, Sodium Cocoyl Glutamate, Sodium Lauryl Glucose Carboxylate (Plantapon SF) Cocoamidoproyl Betaine 18.0 18.0 18.0 18.0 18.0 C 3-Hydroxypropyldecanoate - 0.5 1.0 - - 3-Hydroxypropyl dodecanoate - - - 0.5 1.0 The sulfate-free shampoo formulations were prepared in a manner similar to the sulfate- containing formulations on the basis of the formulations given in the table above. 2. Measurement techniques 2.1 Viscosity measurement After preparation of the shampoo formulations, relative viscosity was measured using a Thermo Scientific Haake RheoStress1 device with the following parameters:

- Geometry: C60/1° Ti L; - temperature 23°C; - shear frequency 10 s

-1. 2.2 Foam evaluation Methods for evaluating the foam of shampoo formulations are known in the art. For example, the foam can be evaluated by an expert panel. Another method is known as Hart- deGeorge blender method: This foam evaluation method incorporates a blender to generate the foam. The foam produced is thick and creamy and very similar to the foam seen in actual use tests. A 200 ml shampoo solution is agitated in a blender (1 liter vessel size) for one minute. The foam is then poured into a funnel placed on a sieve with a mesh of 0.5 mm. The funnel measures 182 mm (top) to 23 mm (bottom). A gauging wire is placed 80 mm from the bottom of the funnel. The time for the level of foam to reach the wire (seconds) is recorded; the higher the number, the better the foam. 3. Results 3.1 Simple (sulfate containing) surfactant formulations The relative viscosity in sulfate containing shampoo formulations are shown in Fig.1. As can be seen in Fig.1, the tested 3-hydroxypropylester generally increased the relative viscosity by at least 3-fold. The viscosity increase varied with the exact ester used and the amount added to the shampoo formulation. For instance, the addition of 1.0% 3- hydroxypropoyl dodecanoate led to a 7-fold increase in viscosity as compared to shampoo without 3-hydroxypropyl ester (referred to as placebo in Fig. 1). While an increase from 0.5% to 1.0% 3-hydroxypropyl ester led to a substantial viscosity increase, a systematic difference (trend) between 3-hydroxypropyl dodecanoate as compared to 3-hydroxypropyl decanoate was not found. Initial results indicated that addition of the tested 3-hydroxypropylesters enhances foam quality of the shampoos. The foam is perceived as thicker and creamier. 3.2 Sulfate free formulations The relative viscosity in sulfate free shampoo formulations is shown in Fig.2.

Fig.2 shows that, also in sulfate-free shampoos, the tested 3-hydroxypropylester increased the relative viscosity several fold as compared to corresponding formulation lacking the 3- hydroxypropylester (referred to as placebo in Fig.2). By far the highest increase was seen with 1.0% 3-hydroxypropoyl dodecanoate. Also for sulfate-free shampoos, the foam quality of the shampoo (in terms of thickness and creaminess) is assumed to be enhanced as a result of addition of the tested 3- hydroxypropylesters. 4. Formulation examples Formulation Anti Oil Shampoo Refreshing Green Body Jello Shampoo sulfate free Antidandruff Shampoo Shampoo Wild Berries Shower Polish All Natural Shower Jelly Aloe Shower Cream Fresh Hair shampoo Virgin Mojito Pre-Shampoo Hair conditioner with UV protection Detox Refreshing Spray for Hair Scalp soothing hair conditioner with UV-B/UV-A Conditioner protection, rinse off Refreshing conditioning Foam Hair Conditioner, leave on Hair Refreshener Mist H

air Styling Hair styling gel Intimate Sensi-Gel Gel Mild femine wash Cleansing Micellar Gel Concentrates & Solid Hair Soap Shampoo Bar Formulations All in one Bar Shampoo body and beard Simple Hand dish wash liquid Dishwash liquid manual Antibacterial HDWL Homecare High performance HDWL with enzymes HDWL 1 HDWL 2 HDWL 3 Cosmetic formulations (compositions) - amounts are indicated as % by weight for all formulations.

.1 Shampoo .1.1 Anti Oil Shampoo Ingredients INCI Amount Aqua/Water Aqua Add 100 SymSave® H Hydroxyacetophenone 0.5 Ucare™ Polymer JR-400 Polyquaternium-10 0.25 Dehyton® K Cocamidopropyl Betaine 10.0 SymDiol® 68 1,2-Hexanediol, Caprylyl Glycol 0.5 1,2 Nonanediol 1,2 Nonanediol 1.0 Texapon HBN Sodium Laureth Sulfate 30.0 Amille GCK-12H Potassium cocoyl Glycinate (and) 6.0 Potassium cocoate (and) Aqua Rewopal® PEG 6000DS PEG-150 Distearate 3.0 Frescolat® ML Menthyl Lactate 0.2 SymControl® Scalp Water (Aqua), Glycerin, Mannitol, 2.0 Tetraselmis Suecica Extract SymMollient® W/S Trideceth-9, PEG-5-Isononanoate, 2.0 Aqua Cremophor® CO 40 PEG-40 Hydrogenated Castor oil 1.0 Surfactant Cosmetic Color Blue 1% sol. CI 42090 0.33 Food Color Tartrazine 0.5% CI 19140 0.12 sol Perfume oil Parfum 1.0 3-Hydroxypropyldecanoate 0.4 Extrapone® Green Tea GW Glycerin, Aqua, Camellia sinensis 0.1 Leaf Extract Citric Acid 30% sol. Aqua, Citric acid 0.15 .1.2 Refreshing Green Body Jello Ingredients INCI Amount Aqua/Water Aqua Add 100 Glycerin 99.5% Glycerin 58.7 Genugel® Carrageenan CG-130 Carrageenan 1.0 Texapon® NSO UP Sodium Laureth Sulfate 15.0 SymOcide® PS Phenoxyethanol, Decylene 0.8 Glycol, 1,2-Hexanediol Frescolat® MGA Plus Menthone Glycerin Acetal, 1.0 Menthol 3-Hydroxypropyldodecanoate 1.0 Actipone Grape Seed GW Aqua, Glycerin, Vitis Vinifera 0.5 Seed Extract SymHair Restore Glyerin, Triticum vulgare protein, 1.0 Aqua Color 1.0 Perfume oil Parfum 1.0

.1.3 Shampoo Sulfate-Free Ingredients EU INCI Amount

Aqua/Water Aqua Add 100 Akypo® Foam RL 40 Sodium Laureth-5 Carboxylate 15.00 Plantacare® 2000 UP Decyl Glucoside 5.00 EDTA NA2 Disodium EDTA 0.10 Phenoxyethanol, Hydroxyacetophenone, Caprylyl 1.45 SymOcide® PH Glycol, Aqua

Aqua/Water Aqua 10.00 Acrylates/Beheneth-25 Novethix™ L-10 Polymer

Methacrylate Copolymer 7.00 Dehyton® PK 45 Cocamidopropyl Betaine 10.00 3-Hydroxypropyldodecanoate 0.80 Trideceth-9, PEG-5 Isononanoate, SymMollient® W/S

Aqua 0.50 Pentylene Glycol, Butylene Glycol, Hydroxyphenyl Propamidobenzoic 1.00 SymCalmin® acid Propylene Glycol, PEG-55 Antil® 141 Liquid

Proplyene Glycol Oleate 2.00 Acusol™ OP 301 Styrene/Acrylates Copolymer 1.00 Glycerin, Triticum Vulgare Protein, SymHair® Restore

Aqua 1.00 Perfume oil Parfum 1.00 .1.4 Antidandruff Shampoo Ingredients INCI Amount Water, distilled Water (Aqua) ad 100 Polymer JR 400 Polyquaternium-10 0.4 Texapon® NSO IS Sodium Laureth Sulfate 40.0 Dehyton K Cocamidopropyl Betaine 8.0 Plantacare 2000 UP Decyl Glucoside 2.0 Citric Acid 10 % solution Citric Acid 0.8 Frescolat® X-cool Menthyl Ethylamido Oxalate 0.5 Caprylyl Glycol, 1,2-Hexanediol, Methylbenzyl 0.8 SymTriol® Alcohol 3- 0.3 Hydroxypropyldecanoate Crinipan® AD Climbazole 0.5 SymMollient® W/S Trideceth-9, PEG-5 Isononanoate, Water (Aqua) 2.0 Tinogard® Q Tri(tétramethylhydroxypiperodonol) Citrate 0.02 Sodium Chloride Sodium Chloride 0.5 Colour I Colour 0.3 Colour II Colour 0.1

Perfume oil

0.4

.1.5 Wild Berries Shower Polish Ingredients EU INCI Amount

Aqua Aqua Add 100 Glycerin 99.5% Glycerin 3.0 Genuvisco® CG-131 Carrageenan 0.7 Keltrol® CG-SFT Xanthan Gum 0.3 3-Hydroxypropyldecanoate 1.5 Sodium Cocoyl Glutamate, Amisoft CS-22

Disodium Cocoyl Glutamate 20.0 Eucarol AGE/EC Disodium Coco-Glucoside Citrate 7.0 Phenoxyethanol, Decylene Glycol, SymOcide PS

1,2 Hexanediol 1.0 Simmondsia Chinensis (Jojoba) Jojoba oil

Seed Oil 8.0 Water (Aqua), Glycerin, Mannitol, SymControl® Scalp

Tetraselmis Suecica Extract 2.0 Water (Aqua), Glycerin, Lycium Actipone® Goji Berry GW

Barbarum Fruit Extract 2.0 Vitacel® CS250g Cellulose 2.0 .1.6 All Natural Shower Jelly Ingredients EU INCI Amount W

ater demin Aqua Add 100 G

lycerin 85% Glycerin, Aqua 25.0 Aqua, Glycerin, Sodium Dermosoft® 1388 ECO

Levulinate, Sodium Anisate 3.0 S

ymMollient® S green Cetearyl Nonanoate 1.5 C

rinipan® PMC green Propanediol Caprylate 0.5 3

-Hydroxypropyldodecanoate 1.2 C

itric Acid Solution 10% Aqua, Citric acid 9.0 G

enuvisco® CG-131 Carrageenan 2.0 P

erfume oil Parfum 0.5 P

lantacare® 2000 UP Decyl Glucoside 20.0 Sodium Cocoyl Glutamate, Disodium Cocoyl Glutamate, 20.0 Amisoft® CS-22 Water

.1.7 Aloe Shower Cream Ingredients EU INCI Amount

Water demin. Water Add 100 Glycerin 85% Glycerin, Water 3.0 Glycerin, Water, Sodium Levulinate, Dermosoft ® 1388 ECO

Sodium Anisate 3.5 Genuvisco® CG-131 Carrageenan 0.8 Keltrol® CG-SFT Xanthan Gum 0.3 3-Hydroxypropyldecanoate 0.1 Sodium Cocoyl Glutamate, Disodium Amisoft® CS-22

Cocoyl Glutamate, Water 20.0 Plantacare® 2000 UP Decyl Glucoside 7.0

Aloe Vera Gel Concentrate Aloe Barbadensis Leaf Juice 1.5 Glycine Soja (Soybean) Oil, Gossypium Herbaceum (Cotton) Seed Oil, Mangifera Indica (Mango) Seed Butter, Olea Europaea (Olive) Fruit Oil, Persea Gratissima 5.0 (Avocado) Oil, Prunus Amygdalus Dulcis (Sweet Almond) Oil, Theobroma Cacao (Cocoa) Seed SymOleo® Vita 7 Butter

Citric acid solution 10% Aqua, citric acid 6.7 Perfume oil Parfum 0.4 Mannitol, Microcrystalline Cellulose, Aloe Barbadensis Leaf Juice Powder, Chromium Oxides greens, 2.0 Cosmopheres® GYAM-M Iron Oxides .1.8 Fresh Hair shampoo Ingredients EU INCI Amount A

qua Aqua Add 100 E

DTA B Powder Disodium EDTA 0.1 N

ativacare™ 5600 Zea Mays (Corn Starch) 2.0 R

heocare® XGN Xanthan Gum 0.5 T

exapon® NSO UP Sodium Laureth sulfate 35.0 D

ehyton® K Cocamidopropyl betaine 8.0 3

-Hydroxypropyldecanoate 0.6 P

lantacare® 2000 UP Decyl Glucoside 4.0 P

erfume oil Parfum 1.0 0.5 SymSave® H Hydroxyacetophenone H

ydrolite® 6 1,2-Hexanediol 1.0

0.3 SymClariol® Decylene Glycol 1.0 Frescolat® ML cryst Menthyl Lactate Pentylene Glycol, Butylene Glycol, Hydroxyphenyl propamidobenzoic 0.2 SymCalmin® acid C

rinipan® AD Climbazole 0.2 P

ropylene Glycol Propylene Glycol 2.0 Pentylene Glycol, Aqua, Glycerin, Triticum vulgare bran extract, 1,2- 1.0 SymHair® Shield Hexanediol, Capryly glycol S

odium Hydroxide 10% solution Aqua, Sodium hydroxide 2.2 Aqua, Butylene Glycol, Malic acid, Actinidia chinensis fruit extract, 0.2 citrus aurantium dulcis juice, citrus Actipone® Alpha-Pulp paradise juice,pyrus malus juice .1.9 Virgin Mojito Pre-Shampoo Ingredients EU INCI Amount

Aqua/Water Aqua Add 100 Nativacare™ 5600 Zea (Mays) Corn Starch 1.0 Keltrol® CG- SFT Xanthan Gum 0.5 Glycerin Glycerin 2.0 SymSave® H Hydroxyacetophenone 0.5 Hydrolite® 5 green Pentylene Glycol 3.0 PEG-40 Hydrogenated castor oil, Trideceth-9, Propylene Glycol, 3.0 Solubilizer Aqua

3-Hydroxypropyldodecanoate 0.2 Diethylhexyl Syringylidenemalonate, 0.1 Oxynex® ST Liquid Caprylic/capric triglyeride

Frescolat® Plus Menthol, Menthyl Lactate 1.0 Perfume oil Parfum 0.5 Maltodextrin, Lactobacillus SymReboot™ L19

ferment 0.5 Propylene Glycol, Aqua, Citrus Extrapone® Lime

aurantifolia juice 1.0 Aqua, CI19140, Sodium Chloride, Color I: FD&C Yellow no.5 -0.01% solution

Sodium Sulfate 0.8 Aqua, CI42090, Sodium Chloride, Color II: FD&C Blue no.1 -0.01% solution

Sodium Sulfate 0.4

0.2 Sodium Hydroxide 10% solution Aqua, Sodium Hydroxide 4.2 Conditioner 4.2.1 Hair conditioner with UV protection Ingredients INCI Amount Renex™ PEG 6000 PEG-150 2.5 3-Hydroxypropyldecanoate 0.2 Hair Conditioner Base Cetyl alcohol, behentrimonium 3.0 chloride, Triticum Vulgare (Wheat) bran extract, linoleic acid PCL-Solid Stearyl heptanoate, stearyl caprylate 0.5 Dowsil™ 5200 Laurylmethicone copolyol 0.5 Natrosol™ 250 HR Hydroxyethylcellulose 0.5 Benzophenone-4 Benzophenone-4 1.0 Neo Heliopan® AP Disodiumphenyldibenz-imidazole 1.0 tetrasulphonate Amino methyl propanol Amino methyl propanol 2.0 Xiameter® 949 MEM-0949 Amodimethicone, cetrimonium 2.0 Emulsion chloride, trideceth-12 Perfume oil Parfum 0.8 Hydrolite®6 1,2-Hexanediol 0.5 Water Water (Aqua) ad 100 4.2.2 Detox Refreshing Spray for Hair Ingredients INCI Amount Frescolat® ML Menthyl Lactate 0.5 N-Ethyl-p-menthane-3- 0.4 carboxamide (Cooling Agent WS-3) Ethyl Menthane Carboxamide Perfume oil Parfum 1.0 S

olubilizer PEG-40 Hydrogenated castor oil, 6.0 T

rideceth.9, Propylene Glycol, Aqua 3-Hydroxypropyldecanoate 0.1 Aqua/Water Aqua Add 100 S

ymOcide® PS Phenoxyethanol, Decylene Glycol, 1,2 1.0 H

exanediol

Ingredients INCI Amount Aqua, Pentylene Glycol, Glycerin, 2.0 Fructose, Urea, citric Acid, sodium Hydrovition® PLUS 2290 hydroxide, Maltose, Sodium PCA, Sodium chloride, Sodium Lactate, Trehalose, Allantoin, Sodium Hyaluronate, Glucose Dragosine® Carnosine 0.2 SymHair® Shield Pentylene Glycol, Aqua, Glycerin, 1.0 Triticum vulgare bran extract, 1,2- Hexanediol, Caprylyl Glycol Citric Acid 30% sol. Aqua, Citric Acid 0.1 .2.3 Scalp soothing hair conditioner with UV-B/UV-A protection, rinse off Ingredients INCI Amount Frescolat® Plus Menthol, Menthyl Lactate 0.3 Crinipan® PMC green Propanediol caprylate 0.5 3- 0.7 Hydroxypropyldodecanoate Abil® 350 Dimethicone 0.1 Dehyquart® A CA Cetrimonium Chloride 0.5 Dehyquart® SP Quaternium-52 4.0 Dracorin® CE Glyceryl Stearate Citrate 1.0 EDETA BD Disodium EDTA 0.1 Extrapone® Green Tea GW Glycerin, Water (Aqua), Camellia 0.7 Sinensis Leaf Extract Perfume oil Parfum 0.5 Lara Care® A-200 Galactoarabinan 0.5 Neutral Oil Caprylic/Capric Triglyceride 1.0 PCL-Liquid® 100 Cetearyl Ethylhexoate 0.3 PCL Solid Stearyl Heptanoate, Stearyl Caprylate 3.0 SymOcide®PS Phenoxyethanol, Decylene Glycol, 1.0 1,2-Hexanediol Water (demineralized) Water (Aqua) ad 100 .2.4 Refreshing conditioning Foam Ingredients EU INCI Amount

Aqua/Water Aqua Add 100 Edeta BD Disodium EDTA 0.05 SymSave® H Hydroxyacetophenone 0.5 PEG-40 Hydrogenated Castor oil, Trideceth-9, Propylene Glycol, 1.5 Solubilizer Aqua

Hydrolite® 5 green Pentylene Glycol 0.5 Frescolat® Plus Menthol, Menthyl Lactate 0.5 3-Hydroxypropyldodecanoate 0.1

Aqua, Pentylene Glycoll, Sodium Lauryl Sulfoacetate, Sodium Oleoyl Sarcosinate, Sodium Chloride, 5.0 SymSol® PF-3 Sodium Oleate

Perfume oil Parfum 1.0 Pentylene Glycol, Butylene Glycol, Hydroxyphenyl Propamidobenzoic 2.0 SymCalmin® acid

Citric Acid 50% sol Aqua, Citric Acid 0.05 .2.5 Hair conditioner, leave on Ingredients INCI Amount Rheocare® XGN Xanthan Gum 0.1 KelcoGel® CG-HA Gellan Gum 0.1 Dehyquart® A CA Cetrimonium Chloride 0.2 Dehyquart® SP Quaternium-52 2.0 Dracorin® CE Glyceryl Stearate Citrate 1.0 Drago-Calm® Water, Glycerin, Avena Sativa (Oat) 2.0 Kernel Extract Farnesol Farnesol 0.05 Perfume oil Parfume 0.5 Lara Care® A-200 Galactoarabinan 0.1 Ucare™ Polymer JR 400 Polyquaternium-10 0.1 Propylene Glycol Propylene Glycol 0.8 SymMollient® WS Trideceth-9, PEG-5 Isononanoate, 1.0 Water SymSol®PF3 Water, Pentylene Glycol, Sodium 1.5 Lauryl Sulfoacetate, Sodium Oleoyl Sarcosinate, Sodium Chloride, Disodium Sulfoacetate, Sodium Oleate, Sodium Sulfate 3-Hydroxypropyldecanoate 0.4 SymTriol® Caprylyl Glycol, 1,2-Hexanediol, 1.0 Methylbenzyl Alcohol Water (demineralized) Water (Aqua) ad 100 .2.6 Hair Refresher Mist Ingredients EU INCI Amount Lauryl alcohol, Phenoxyethanol, 2- SymDeo® Plus

Benzyleptanol, Decylene Glycol 0.5 Perfume oil Parfum 0.1 Frescolat® ML nat Mentyl Lactate 0.3 3-Hydroxypropyldecanoate 1.0 Crinipan® PMC green Propanediol Caprylate 0.3

PEG-40 Hydrogenated Castor oil, Trideceth-9, Propylene glycol, 5.0 Solubilizer Aqua Pentylene Glycol, Butylene Glycol, Hydroxyphenyl Propamidobenzoic 0.2 SymCalmin® acid Water (Aqua), Glycerin, Mannitol, SymControl® Scalp

Tetraselmis Suecica Extract 2.0 Genuvisco® CG-131 Carrageenan 0.2 Propylene Glycol Propylene Glycol 3.0 Butylene Glycol Butylene Glycol 3.0

Aqua Aqua Add 100 Edeta® BD Disodium EDTA 0.1 Sodium Benzoate Sodium benzoate 0.4 0.5 Colour Glycerin, Aqua, Rosmarinus 0.5 Actipone® Rosemary GW officinalis leaf extract .3 GEL .3.1 Intimate Sensi-Gel Ingredients EU INCI Amount Add Aqua/Water Aqua 100 Sodium Benzoate Sodium benzoate 0.3 Keltrol® CG-T Xanthan Gum 0.2 Cyamopsis Tetragonolobus

Cyamopsis Tetragonolobus Gum Gum

0.1 Glycerin Glycerin 4.0

Tego® Betain F50 Cocamidopropyl betaine 14.0 PEG-40 Hydrogenated castor oil, Trideceth- 3.0 Solubilizer 9, Propylene Glycol, Aqua 1.0 Hydrolite® 6 1,2 Hexanediol Phenylpropanol, o-cymen-5-ol, Decylene 0.3 SymGuard® CD Glycol 0.1 SymRelief® 100 Bisabolol, Zingiber officinale root extract 0.2 Perfume oil Parfum

Frescolat® X-cool Menthyl ethylamido oxalate 0.4 0.7 3-Hydroxypropyldodecanoate 2.0 Plantacare® 2000 UP Decyl Glucoside

Lactic acid 90% Nat.

Lactic Acid, Aqua

0.3

.3.2 Mild feminine wash Ingredients EU INCI Amount Aqua/Water Aqua 73.15 SymSave® H Hydroxyacetophenone 0.5 Keltrol® CG-T Xanthan Gum 0.5 Glycerin Glycerin 2.0 Propylene Glycol Propylene Glycol 3.0 Tego® Betain F50 Cocamidopropyl betaine 14.0 SymGuard® CD Phenylpropanol, o-cymen-5-ol, Decylene Glycol 0.3 3-Hydroxypropyldecanoate 1.0 Plantacare 2000 UP Decyl Glucoside 2.0 Glycerin, Aqua, Hamamelis Virginiana Bark/- Extrapone® Witch Hazel GW Leaf/Twig Extract 1.0 PEG-40 Hydrogenated castor oil, Trideceth-9, Solubilizer Propylene Glycol, Aqua 1.5 Perfume oil Parfum 0.2 Pentylene Glycol, Butylene Blycol, SymCalmin® Hydroxyphenyl propamidobenzoic acid 1.0 Lactic acid 90% Nat. Lactic Acid, Aqua 0.32 .3.3 Cleansing Micellar Gel Ingredients INCI Amount Water, distilled Water (Aqua) Ad 100 Carbopol® ETD 2050

Polymer Carbomer 0.7 Aqua, Pentylene glycol, Glycerin,Fructose,Urea, Citric acid, Sodium hydroxide, Maltose,Sodium pca, Sodium Hydroviton® PLUS 2290 chloride 2.0 Sodium lactate, Trehalose, Allantoin, Sodium hyaluronate Glucose SymOcide® PS Phenoxyethanol, Decylene glycol, 1,2-hexanediol 1.0 Sodium Hydroxide 10%

solution Aqua, Sodium Hydroxide 3.28 SymMollient® W/S Trideceth-9, PEG-5 Isononanoate, Aqua 1.0 Aqua, Pentylene glycol, Sodium lauryl SymSol® PF-3 sulfoacetate, Sodium oleoyl sarcosinate, Sodium 3.0 chloride, Sodium oleate

3-

Hydroxypropyldodecanoate 0.8 Perfume oil Parfum 1.0 SymVital® AR Zingiber officinale (ginger) root extract 0.2 Extrapone® Seaweed Aqua, Butylene glycol, Fucus vesiculosus extract 1.0 Actipone® Dandelion Juice

(Organic) GW Glycerin, Taraxacum officinale juice, Aqua 1.0 Colour I Colour 0.35 Colour II Colour 0.20 Caprylhydroxamic Acid Caprylhydroxamic Acid 0.2 Phenylpropanol Phenylpropanol 0.2 .4 Concentrate & Solid formulations: .4.1 Sensi-SCALP (Green Solid Shampoo) Ingredients EU INCI Amount

AMISOFT® MS-11 Sodium Myristoyl Glutamate 30.0 3-Hydroxypropyl undec-10-enoate 1.5 ELFAN® AT 84 Sodium cocoyl Isethionate 15.0 ImerCare® 02K-S Kaolin 18.8 Hydrolite® 5 green Pentylene Glycol 1.5 Dragosantol® 100 Bisabolol 0.1 Potassium Sorbate Potassium Sorbate 0.3 Aqua/Water Aqua Add 100 Caprylic/Capric Triglyceride, SymDecanox™ HA

Hydroxymethoxyphenyl decanone 1.5 Alpha Tocopherol DL Tocopherol 0.5 Cetiol® SB45 Butyrospermum parkii butter 13.0 Aqua, Glycerin, Aspalathus Linearis Extrapone® Rooibus GW

leaf extract 1.0 SymReboot™ L19 Maltodextrin, Lactobacillus Ferment 0.5 Glycine soja oil, Gossypium herbaceum seed oil, mangifera idica seed butter, olea europaea fruitoil, persea gratissima oil, 1.0 prununs amygdalus dulcis (sweet almond) oil, Theobroma cacao seed SymOleo® Vita7 butter

Perfume oil Parfum 1.2

.4.2 Hair Soap SHAMPOO Bar Ingredients EU INCI Amount

Talco Talc Add 100 Microcrystaline Cellulose, Vivapur® CS 032 XV

Xanthan Gum 0.30 Texapon® ZACD Sodium Lauryl Sulfate 10.00 3-Hydroxypropyl undec 10-enoate 1.10 Glycine soja oil, Gossypium herbaceum seed oil, mangifera idica seed butter, olea europaea fruitoil, persea gratissima oil, prununs 2.00 amygdalus dulcis (sweet almond) oil, Theobroma cacao SymOleo® Vita7 seed butter

Cetiol® SB 45 Butyrospermum parkii butter 3.00 Mackamide® CMA Cocamide Mea 4.00 Aqua, Pentylene Glycol, Sodium Lauryl sulfoacetate, sodium oleoyl sarcosinate, 5.00 Sodium Chloride, Sodium SymSol® PF-3 Oleate Helianthus annuus (Sunflower) seed oil, Beta-Carotene 0.45 Food Color Beta Carotene E160A OilSoluble (CI40800) Phenoxyethanol, Hydroxyacetophenone, 1.00 SymOcide® PH Caprylyl Glycol, Aqua Glycerin, Triticum vulgare 1.00 SymHair® Restore protein, Aqua 1.50 Perfume oil Parfum .4.3 All in one bar- Shampoo- body- beard Ingredients EU INCI Amount T

ego® Alkanol 1618 Cetearyl Alcohol 29.3 T

ego® Feel Green Cellulose 1.0 S

isterna A10E-C Sucrose Tetrastearate Triacetate 2.5 3

-Hydroxypropyl benzoate 1.3 H

ydraSynol™ DOI Isosorbide Dicaprylate 2.0 C

oconutoil Cocos Nucifera (Coconut) Oil 3.3 Theobroma Cacao (Cocoa) Seed Cacao Butter

Butter 2.0 D

ehymuls® SMO Sorbitan Oleate 0.2

Passion Fruit oil Passiflora Edulis Seed Oil 7.0 I

soamyl Laurate Isoamyl Laurate 1.0 T

ocopherol Tocopherol 0.2 Sodium Stearoyl Glutamate, Sodium Amisoft® GS-11P

Cocoyl Glutamate 20.0 H

ostapon® SCI-85 Sodium Cocoyl Isethionate 30.0 P

erfume oil Parfum 1.0 4.5 Hand dish wash / Homecare 4.5.1 Simple Hand dish wash liquid Ingredient w/w% Aqua Ad 100 Sodium Laureth Sulfate (37%) 45.0 Cocoamidopropylbetaine 6.0 3-Hydroxypropyldecanoate 1.0 Ethanol 1.0 Benzisothiazolinone, Methylisothiazolinone, Laurlyamine, Dipropylenediamine 0.1 Sodium Chloride 2.0 Perfume 0.2 4.5.2 Dishwash liquid manual Ingredient w/w% Sodium Laureth Sulfate (37%) 82.74 Cocoamidopropylbetaine 10.0 3-Hydroxypropyldodecanoate 0.9 Ethanol 1.0 Benzisothiazolinone, Methylisothiazolinone, Laurlyamine, Dipropylenediamine 0.1 Sodium Chloride 0.6 Perfume 0.4 1,2-Propanediol 5.0 Sodium Hydroxyide (30% sol) 0.16 4.5.3 HDWL a) Antibacterial HDWL Ingredient w/w% Aqua Ad 100 Sodium Laureth Sulfate 7.0 C8-18 Alkylamidopropylbetaine 2.0

3-Hydroxypropyldodecanoate 1.1 Sodium Chloride 0.5 Citric Acid 1.5 Sodium Benzoate 2.0 Phenoxyethanol 0.5 Camphor oil 0.1 b) High performance HDWL with enzymes Ingredient w/w% Aqua Ad 100 Sodium Laureth Sulfate 20.0 Cocamidopropylbetaine 7.5 3-Hydroxypropyldecanoate 0.7 Sodium Chloride 1.0 Alcohol Denat 4.5 Amine, C12-14-Alkyldimethyl, N-Oxide 3.0 Propylene Glycol 1.5 Sodium P-Cumene Sulfonate 0.5 Potassium Acetate 0.5 Glycerin 0.1 2,6-Dimethyloct-7-em-2-ol 0.1 Protease/Subtilsin 0.2 Amylase 0.2 c) HDWL 1 Ingredient w/w% Aqua Ad 100 Sodium Laureth Sulfate 7.5 Alpha Olefin Sulfonate 7 7.5 3-Hydroxypropyldodecanoate 0.4 Cocamidopropylamineoxide 2.5 Cocamidopropylbetaine 2.5 C10 Pareth-8 2.5 Sodium Chloride 1.0 Sodium Xylene Sulfonate 1.0 Perfumes 0.2 Citric Acid 0.2 Polyethylenimine ethoxylated 0.2 CMIT/ MIT/ BIT 0.05 d) HDWL2 Ingredient w/w% Aqua Ad 100 Sodium Chloride 1.0

Perfumes 0.2 CMIT / MIT / BIT 0.03 3-Hydroxypropyldecanoate 0.5 Ammonium Dodecyl Sulphate 7.5 Ammonium Laureth Sulfate 3.0 Ammonium C12-15 Alkyl Sulfate 3.0 Ammonium C12-15 Pareth Sulfate 3.0 Lauramidopropylamineoxide 2.0 Diethylentriamine Pentaacetate 0.2 e) HDWL3 Ingredient w/w% Aqua Ad 100 Sodium Laureth Sulfate 8.0 Cocamidopropylbetaine 8.0 3-Hydroxypropyldecanoate 1.2 C14-17 Sec Alkyl Sulfonate 8.0 Sodium Chloride 2.0 Perfumes 0.2 Sodium Hydroxide 0.2 CMIT/ MIT /BIT 0.002 2-Propylheptanol ethoxylated propoxylated 2.0 4.5.4 All purpose cleaner a) All purpose cleaner 1 Name Amount Aqua Ad 100 C14-17 Sec Alkyl Sulfonate SAS 3 Sodium Laureth Sulfate 2 Sodium Caronate 1 3-Hydroxypropyldecanoate 0.75 Sodium Bicarbonate 0,5 Phenoxyethanol 0,5 Sodium Cocoate 0,5 Perfume 0,2 Sodium Methylglycine Diacetate 0,2 Sodium Pyrithione 0,05 Fatty Acids C12-18 and C18 unsat. 0,05 Sodium Hydroxide 0,05 b) All Purpose Cleaner Test formulation pH 6.5

Ingredient w/w% Rhamnolipid 0.5 Sophorolipid 2.5 Sodium Citrate 1.3 3-Hydroxypropyl undec 10-enoate 0.3 Sodium Carbonate 0.5 2-Phenoxyethanol 0.1 Sodium Hydroxide q.s to adjust pH 6.5 Water Ad 100 c) All Purpose Spray pH 5-6 Ingredient w/w% Rhamnolipid 1.0 Sophorolipid 1.0 3-Hydroxypropyldecanoate 0.1 Alcohol Denat 3.0 Aqua Ad 100 Preservative, Fragrance q.s 4.5.5 Floor and Kitchen Cleaner a) Floor Cleaner 1 Name Amount Aqua Ad 100 C9-11 Pareth-8 2.5 Propyl heptanol ethoxylated 2.0 Sodium Carbonate 0.5 Sodium Bicarbonate 0.2 Phenoxyethaol 0.5 Perfume 0.3 3-Hydroxypropyldodecanoate 0.8 Tetrasodium EDTA 0.2 Hydroxyethylcellulose 0.2 PPG-2 Butylether 0.2 b) High Gloss Floor Cleaner pH 8 Ingredient w/w% Rhamnolipid 1.0 Sorbitan ester surfactant 0.5 Sodium C14-16 Olefin Sulfonate 4.0 Water Ad 100 Cocamidopropylbetaine 1.0

3-Hydroxypropyldecanoate 0.6 PE Wax 0.5 Preservative q.s. c) Grapefruit Kitchen Cleaner Ingredient w/w% Aqua Ad 100 Sodium Carbonate 1.0 Perfume 0.2 Phenoxyisopropanol 5.0 3

-Hydroxypropyl benzoate 0.9 Tetrasodium Glutamate Diacetate 0.5 Sodium Laureth Sulfate 2.5 Olive Oil Fatty Acid 1.0 Methyl Diethanolamine 2.0 Triethnolamine 1.0 Amide Polyglycol Ether 0.5 Glycerine 0.2